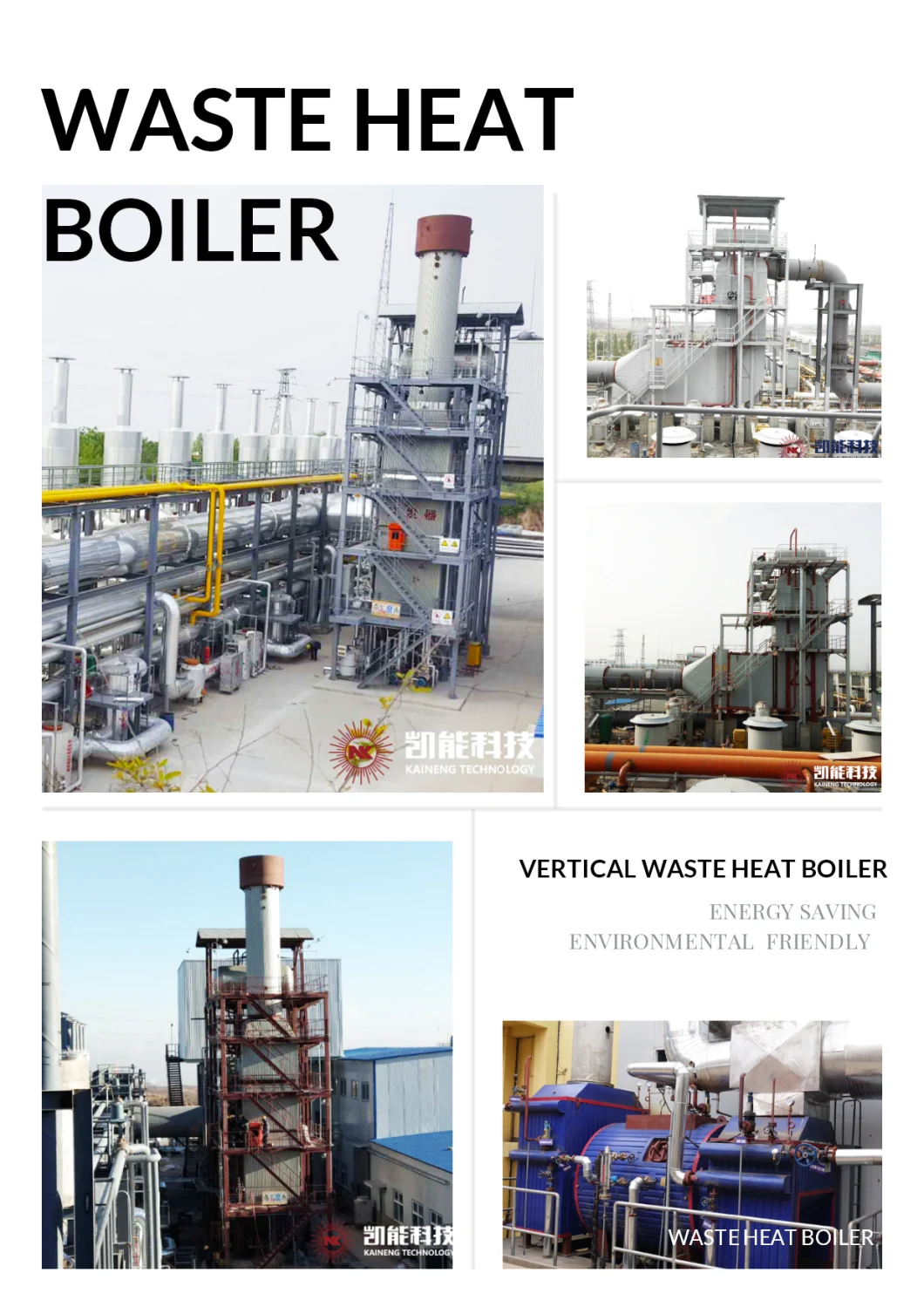

Power Generation Boiler Exhaust Gas Waste Heat Recovery Steam Generator

Description of Heat Recovery Steam Generator:

Heat Recovery Steam Generator is a special high-efficiency energy-saving boiler equipment for the exhaust gas heat recovery of the oil/gas engine set. H fin tubes are used to increase the boiler heating surface on the smoke side of the water tube.

At the same time, the strong turbulence is formed when the flue gas passes through the surface of the H fin tube, which improves the heat transfer efficiency and reduces the soot accumulation. At present, thousands of waste heat boilers have been applied to various types of gas-fired generating units, which have been highly praised by users.

Composition of Exhaust Gas Boiler:

1. Superheater

2. Evaporater

3. Economizer

Product advantage of Heat Recovery Steam Generator:

More Project Cases:

Kaineng Service:

Pre-sale service:

Kaineng helps customer to choose the proper waste heat boiler model according to different requirements of various industry. Before delivery we will provide boiler drawings, auxiliary equipment drawings, foundation drawing, layout drawing, etc.

In-sale service:

Kaineng keeps 24 hours online and keeps close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

1. provide full range of original quality spare parts.

2. Kaineng offer project guidance service, we will dispatch engineers to your local project site to guide the installation and commissioning.

3. Our engineers will held a training for boiler workers to ensure the safe operation.

4. Free maintenance and repair for one year and lifelong service.

Transportation For Exhaust Gas Boiler

Kaineng Factory Area

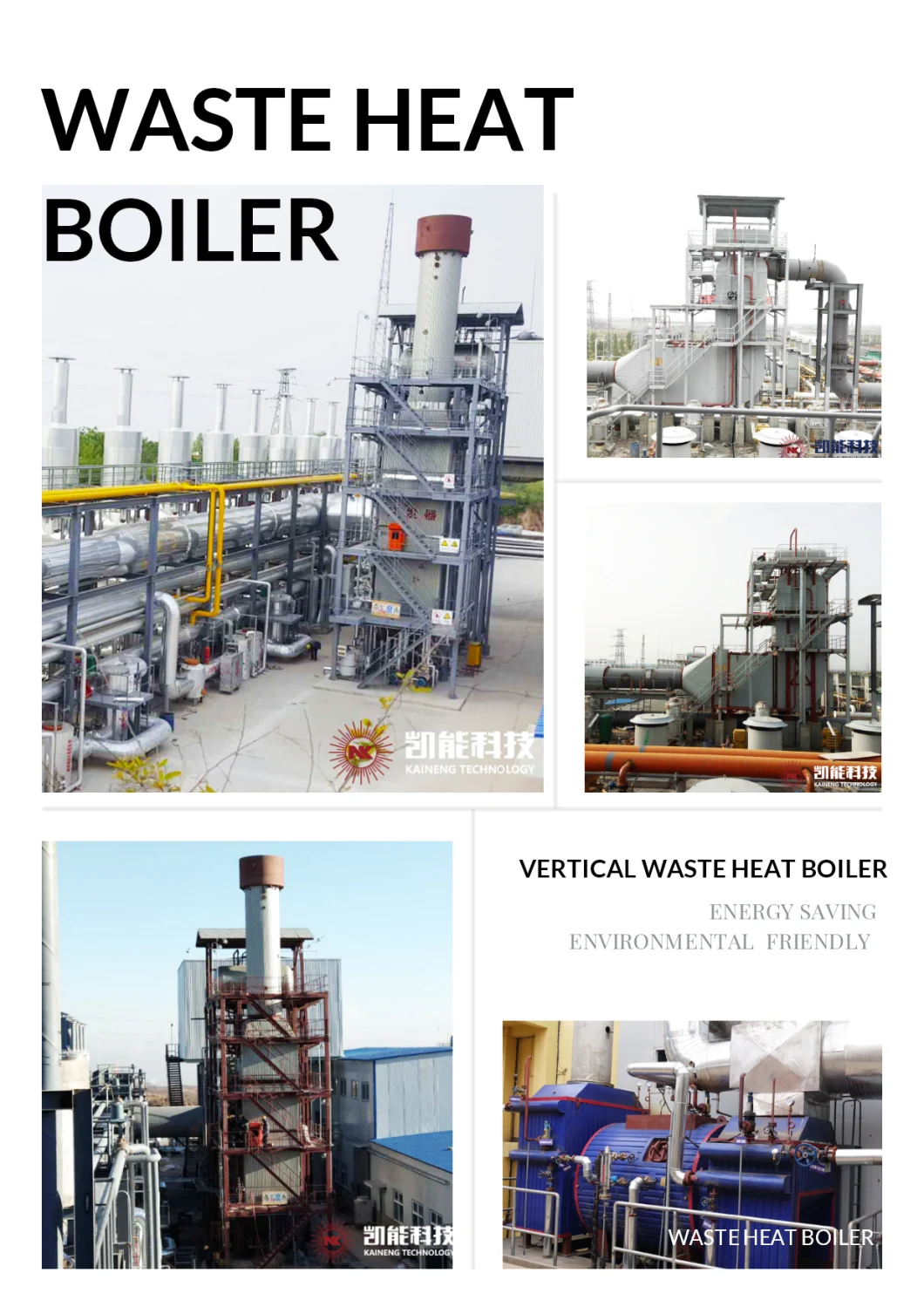

Description of Heat Recovery Steam Generator:

Heat Recovery Steam Generator is a special high-efficiency energy-saving boiler equipment for the exhaust gas heat recovery of the oil/gas engine set. H fin tubes are used to increase the boiler heating surface on the smoke side of the water tube.

At the same time, the strong turbulence is formed when the flue gas passes through the surface of the H fin tube, which improves the heat transfer efficiency and reduces the soot accumulation. At present, thousands of waste heat boilers have been applied to various types of gas-fired generating units, which have been highly praised by users.

Composition of Exhaust Gas Boiler:

1. Superheater

2. Evaporater

3. Economizer

Product advantage of Heat Recovery Steam Generator:

- High heat transfer efficiency. The welding fusion rate of fins with steel pipes can reach up to 95%. low contact resistance, good heat transfer performance.

- Low flow resistance

- Less dust

- Less wear and tear

- Small size and light weight

| 1 | Operating pressure: | 1.0MPa |

| 2 | Design pressure: | 1.1MPa |

| 3 | Operating temperature(inlet/outlet) ºC : | 60/184ºC |

| 4 | Design temperature | 200ºC |

| 5 | Hydraulic test pressure | 1.4MPa |

| 6 | Maximum dimension: | 2885×Φ1525 (mm) |

More Project Cases:

Kaineng Service:

Pre-sale service:

Kaineng helps customer to choose the proper waste heat boiler model according to different requirements of various industry. Before delivery we will provide boiler drawings, auxiliary equipment drawings, foundation drawing, layout drawing, etc.

In-sale service:

Kaineng keeps 24 hours online and keeps close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

1. provide full range of original quality spare parts.

2. Kaineng offer project guidance service, we will dispatch engineers to your local project site to guide the installation and commissioning.

3. Our engineers will held a training for boiler workers to ensure the safe operation.

4. Free maintenance and repair for one year and lifelong service.

Transportation For Exhaust Gas Boiler

Kaineng Factory Area