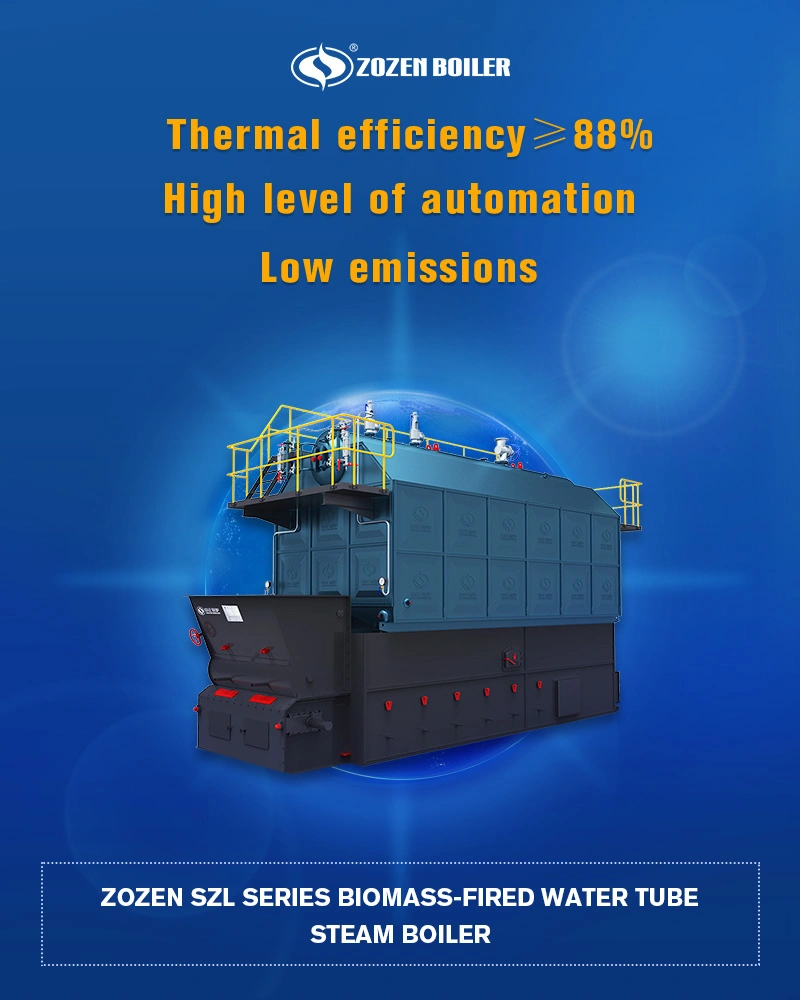

SZL series biomass-fired steam boiler

Sufficient output, low emissions, thermal efficiency above 88%, high level of automationSteam

| Product thermal capacity: | 4-35 t/h |

| Working pressure: | 1.0-2.5 MPA |

| Outlet temperature: | 184-350 ºC |

| Available fuel: | Biomass molding granules, wood chip, corn cob, saw dust |

| Available industries: | Heating, chemical, food, tobacco, textile, print and dyeing, feed, medicine, building materials, wine, hospital |

Introduction

SZL series biomass-fired steam boiler is package or shop-assembled water tube boiler with double steam drum and chain grate stoker structure. 4-6 tph boiler is package boiler and 6-35 tph is shop-assembled structure, which is composed of 2 parts, upper part is heat absorbing surface and lower part is combustion equipment. The former part of boiler body is surrounded by membrane wall, its upper part connects with boiler drum and lower part connects with header, which forms a combustion chamber to absorb the radiated heat from furnace; there are dense convection tube bundle between the back side of upper and lower drum, the high temperature smoke enters a separate economizer after flushing heat absorbing surface then discharge from chimney.

Technical advantages

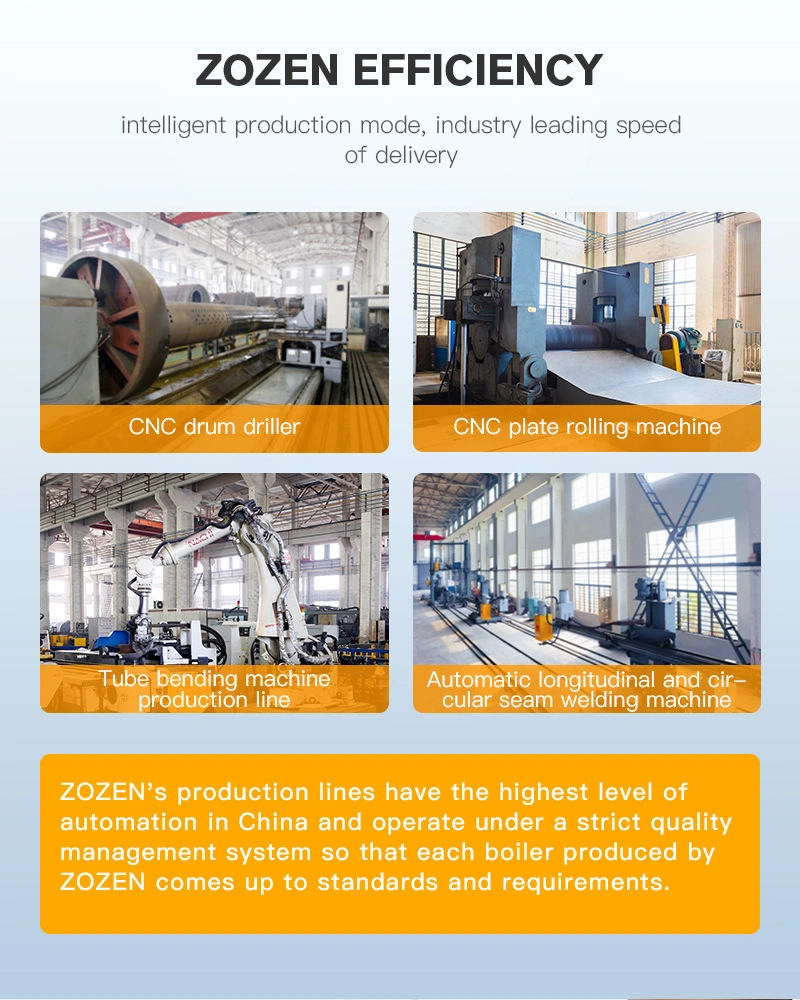

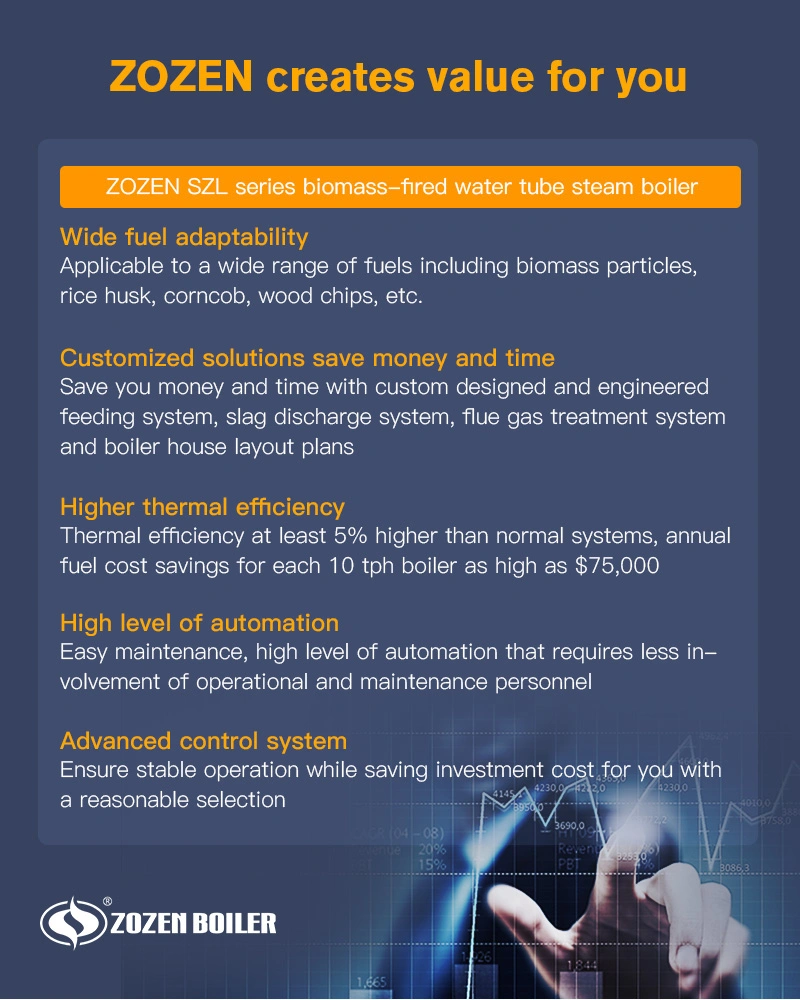

CNC manufacturing technology

The key processing technologies such as steel plate blanking, circling, drum and tube plate drilling adopt advanced CNC machining to reduce the assembly stress and prolong the service life of the boiler.

Steel tube cutting, thread tube pressing and convection tube processing all adopt advanced CNC technology.

Automatic production line.

The welding of important parts like the vertical and circular seams of the boiler, the tubes, the inside of boiler and the flange are all adopted automated welding processes such as submerged arc welding or gas shielded welding to ensure the welding quality. All the vertical and circular seams will be done 100% radiographic inspection.

Tube flange weld adopts robot welding.

The chain grate panel, front and rear smoke chamber panel adopts CNC plasma cutting machine to cut orderly and beautifully.

Unique structural designAccording to different capacity, different numbers of independent air bins are arranged from front to back of the grate.

The user can reasonably adjust the air distribution according to different combustion conditions to ensure that the fuel is fully burnt.

Secondary air is input to disturb fuel gas in the furnace, to ensure the fuel is burnt totally. The independent secondary fan makes it easy to control and adjust the air volume and air pressure.

Feeds evenly feeding and avoid flashback.

Low NOx emissionsGraded air supply and special furnace arch structure decrease the NOx emissions to 100mg/m³.

Different biomass raw materials are analyzed by numerical simulations, thermal efficiency is more than 90%

| Product thermal capacity: | 4-35 t/h |

| Working pressure: | 1.0-2.5 MPA |

| Outlet temperature: | 184-350 ºC |

| Available fuel: | Biomass molding granules, wood chip, corn cob, saw dust |

| Available industries: | Heating, chemical, food, tobacco, textile, print and dyeing, feed, medicine, building materials, wine, hospital |

| Model | Rated thermal power(t/h) | Rated working pressure(MPa) | Steam temperature | Feed water temperature |

| SZL4-1.25-M | 4 | 1.25 | 194 | 20 |

| SZL4-1.60-M | 4 | 1.6 | 204 | 20 |

| SZL4-2.45-M | 4 | 2.45 | 225 | 20 |

| SZL6-1.25-M | 6 | 1.25 | 194 | 20 |

| SZL6-1.60-M | 6 | 1.6 | 204 | 20 |

| SZL6-2.45-M | 6 | 2.45 | 225 | 20 |

| SZL8-1.25-M | 8 | 1.25 | 194 | 20 |

| SZL8-1.60-M | 8 | 1.6 | 204 | 20 |

| SZL8-2.45-M | 8 | 2.45 | 225 | 20 |

| SZL10-1.25-M | 10 | 1.25 | 194 | 20 |

| SZL10-1.60-M | 10 | 1.6 | 204 | 20 |

| SZL10-2.45-M | 10 | 2.45 | 225 | 20 |

| SZL20-1.25-M | 20 | 1.25 | 194 | 20 |

| SZL20-1.60-M | 20 | 1.6 | 204 | 20 |

| SZL20-2.45-M | 20 | 2.45 | 225 | 20 |

| SZL30-1.25-M | 30 | 1.25 | 194 | 20 |

| SZL30-1.60-M | 30 | 1.6 | 204 | 20 |

| SZL30-2.45-M | 30 | 2.45 | 225 | 20 |

| SZL35-1.25-M | 35 | 1.25 | 194 | 20 |

| SZL35-1.60-M | 35 | 1.6 | 204 | 20 |

| SZL35-2.45-M | 35 | 2.45 | 225 | 20 |

Wuxi Zozen Boilers Co., Ltd. was founded in 1988. After 30 years development, manufacturing base covers hundreds of thousands of square meters. It ranks top in the industrial boiler sector in Asia in terms of the variety of its products, the level of automation in its manufacturing facility and the volume of its production. ZOZEN prides itself on an annual production capacity of over 2,000 industrial boilers.

Nowadays, ZOZEN's products have been exported to more than 100 countries and regions around the world and are used for application in chemical, pharmaceutical, paper, textile, food, electronics, automobile manufacturing, furniture, pesticides, biological products, building materials and many other industries.